How to make anilox roller for flexographic printing machine

Most printing both field, line, and continuous image. In order to meet the needs of various printing products, users must not take flexo printing machine with a few printing units with a few roller practice. Take the narrow range unit flexo printing machine as an example, at present, the introduction of 6+1, that is 6 color groups for multi-color printing, the last unit can be printed and UV glazing.

We suggest that for printing not more than 150 lines, this 6+1 flexo printing machine should be equipped with 9pcs of anilox rollers. Four pcs of700-line anilox rollers with a thickness of 2.3BCM (1 billion cubic micron/inch) and 60° are used for layer printing. 3pcs of 360 ~ 400 lines, BCM6.0, 60° roller for field printing; 2pcs of 200 lines, BCM15 or so, 60° roller for printing gold and glazing. If you use water-based light oil, you should choose the 360 line roller, so that the oil layer is slightly thinner, will not affect the printing speed because of the dry light oil. Water-based gloss does not have the special smell of UV gloss. The device of anilox roller can be determined by test and comparison during printing. The thickness of ink layer observed by the operator in the test process mainly depends on the line number and BCM value of anilox roller.

Anilox roller in the use process should pay attention to what problems

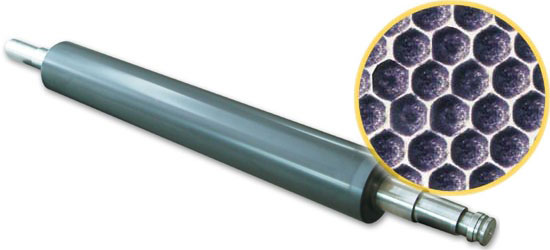

Here we say roller is laser engraving ceramic roller, it is used in aviation, aerospace, high temperature resistance, wear resistance coating materials, according to a certain density, depth and a certain Angle, shape, with laser engraving. This roller is characterized by high cost, wear resistance, if used properly, its life can be up to several years; If used improperly, not only the life will be shortened, but also the roller scrap.

In the process of use, the position of a roller on the printing press depends on the specific printing, different printing, roller position is also different, so printing often have to replace the wire roller. At present, the narrow width machine is mainly used for solid steel roller, very heavy, when installing the roller to avoid the surface cover of the roller into other metal items. Because the ceramic coating is very thin, it is easy to cause permanent damage on impact. In the process of printing and cleaning machine, ink should be avoided on the roller dry, to use special detergent recommended by water-based ink manufacturers, using steel brush to wash, to ensure clean and thorough cleaning. And develop the habit of often using high magnifying glass to observe the roller mesh hole, once found that ink deposition to the bottom of the mesh hole and a gradual increase in the trend, should be cleaned in time. If the above method does not work, ultrasonic or sandblasting can be used for treatment, but must be carried out under the guidance of roller manufacturers.

Under normal use and maintenance conditions, there is no need to worry about roller wear, the main wear parts of the ink transfer system is the scraper, in contrast, roller ceramic coating wear can be said to be minimal. After roller slight wear, the ink layer will be thinner.

What is the relationship between the number of printing network lines and the number of network lines of the roller

In many articles introducing flexographic printing technology, the ratio of the number of printing network lines to the number of roller network lines is set as 1∶3.5 or 1∶4. Based on practical experience and analysis of the products awarded by the American Flexographic Technology Association (FTA) in recent years, the author believes that the value should be higher, about 1:4.5 or 1:5, and for some fine printing products, the ratio may be even higher. The reason is that the most difficult problem to solve when using flexographic printing layer is dot expansion. The roller with a higher number of network lines is selected, and the ink layer is thinner. The dot expansion deformation is easier to control. When printing, if the ink is not thick enough, you can choose a water-based ink with a higher color concentration to ensure the quality of printing products.

Post time: Jun-15-2022