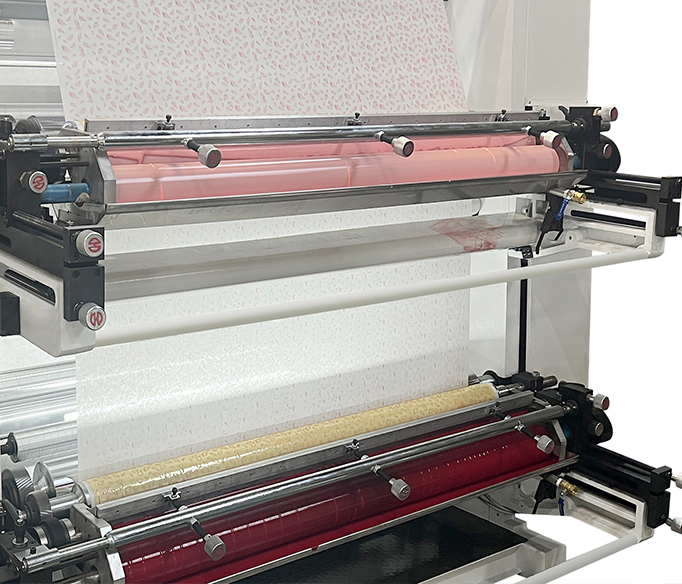

1. Unwind unit adopts single-station or double-station structure; 3″air shaft feeding; Automatic EPC and constant tension control;With refueling warning, break material stop device.

2. The main motor is controlled by frequency conversion, and the whole machine is driven by high-precision synchronous belt or servo motor.

3. The printing unit adopts ceramic mesh roller for ink transfer, single blade or chamber doctor blade, automatic ink supply; Anilox roller and plate roller automatic separating after stop; The independent motor drives the anilox roller to prevent ink from solidifying on the surface and blocking the hole.

4. Rewinding pressure is controlled by pneumatic components.

5. Rewind unit adopt single-station or double-station structure; 3 “air shaft; Electric motor drive, with closed – loop tension control and material – breaking stop device.

6. Independent drying system: electric heating drying (adjustable temperature).

7.The whole machine is centrally controlled by PLC system; Touch screen input and display the working state; automatic meter counting and multi – point speed regulation.

Sample display

Stack flexo printing press has a wide range of application materials and is highly adaptable to var-ious materials, such as transparent film, non-wo-ven fabric, paper, etc