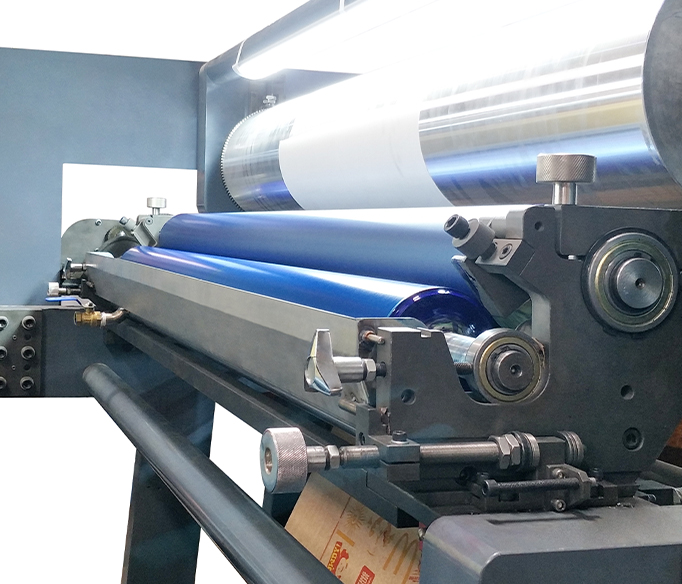

1.The flexo printing machine can perform double-sided printing by changing the conveying route of the substrate.

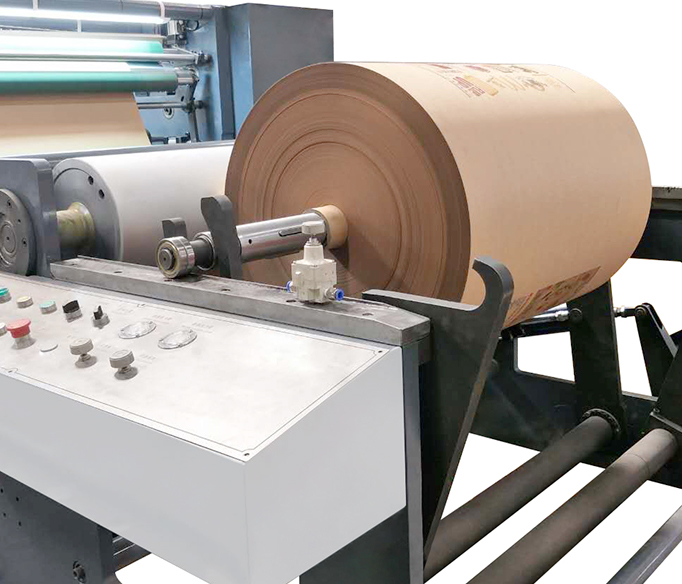

2.The printing material of the printing machine is a single sheet of paper, kraft paper, paper cups and other materials.

3.The raw paper unwinding rack adopts single-station air expansion shaft automatic unwinding method.

4.The tension is taper control technology to ensure the accuracy of overprinting.

5.The winding is driven by a motor, and the floating roller structure realizes closed-loop tension control.