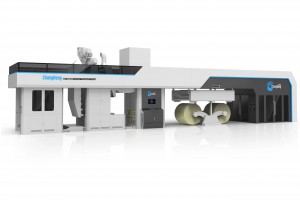

1.Using sleeve technology:sleeve has a quick version change feature, compact structure, and lightweight carbon fiber structure. The required printing length can be adjusted by using sleeves of different sizes.

2.Rewinding and unwinding part:The rewinding and unwinding part adopts an independent turret bidirectional rotation dual-axis dual-station structure design, and the material can be changed without stopping the machine.

3.Printing part:Reasonable guide roller layout makes the film material run smoothly; the sleeve plate change design greatly improves the speed of plate change; the closed scraper reduces solvent evaporation and can avoid ink splashing; the ceramic anilox roller has high transfer performance, the ink is even, smooth and strong durable;

4.Drying system: The oven adopts a negative pressure design to prevent hot air from flowing out, and the temperature is automatically controlled.

Sample display

Gearless Cl flexo printing press has a wide range of application materials and is highly adaptable to various materials, such as transparent film, non-woven fabric, paper, paper cups etc.

.jpg)